In a world where businesses race to do more with less, the pressure to perform often comes at a steep cost – overworked teams, strained resources, and a planet pushed to its limits. But what if you could supercharge productivity without leaving a trail of environmental damage? That's where Midwest Elastomers Inc. (MEI) steps in, offering a revolutionary approach that proves you don't have to choose between getting ahead and giving back. Based in Wapakoneta, Ohio, MEI isn't just grinding rubber – they're grinding the path to a greener, more efficient future.

How the size of rubber granules directly influences product performance

Granule size affects the physical properties of the final product. For example, in sports surfaces like artificial turf or running tracks, smaller, uniform granules can improve shock absorption, durability, and surface consistency, enhancing safety and playability. Larger or uneven granules might lead to inconsistent texture, reduced elasticity, or faster wear, compromising performance. In industrial applications or plastics blending, granule size impacts how well the rubber integrates with other materials, affecting strength, flexibility, or processing efficiency.

How the size of rubber granules directly influences its sustainability impact

The size of rubber granules is a critical factor in driving resource efficiency and delivering powerful environmental outcomes. Finer granules, crafted through precise grinding processes like those at Midwest Elastomers, optimize material use and minimize waste, paving the way for innovative green rubber products. These smaller granules also enable the creation of lighter, thinner products that rely on less raw material overall, maximizing sustainability without compromising quality. On the flip side, poorly sized granules can trigger excess energy consumption during production or lead to products that break down quickly, adding to landfill burdens. With expertly tailored granule sizes, green rubber products gain extended lifespans and enhanced recyclability, amplifying their eco-friendly impact and offering unmatched advantages for industries and the planet alike.

Productivity, Redefined with Precision Processes

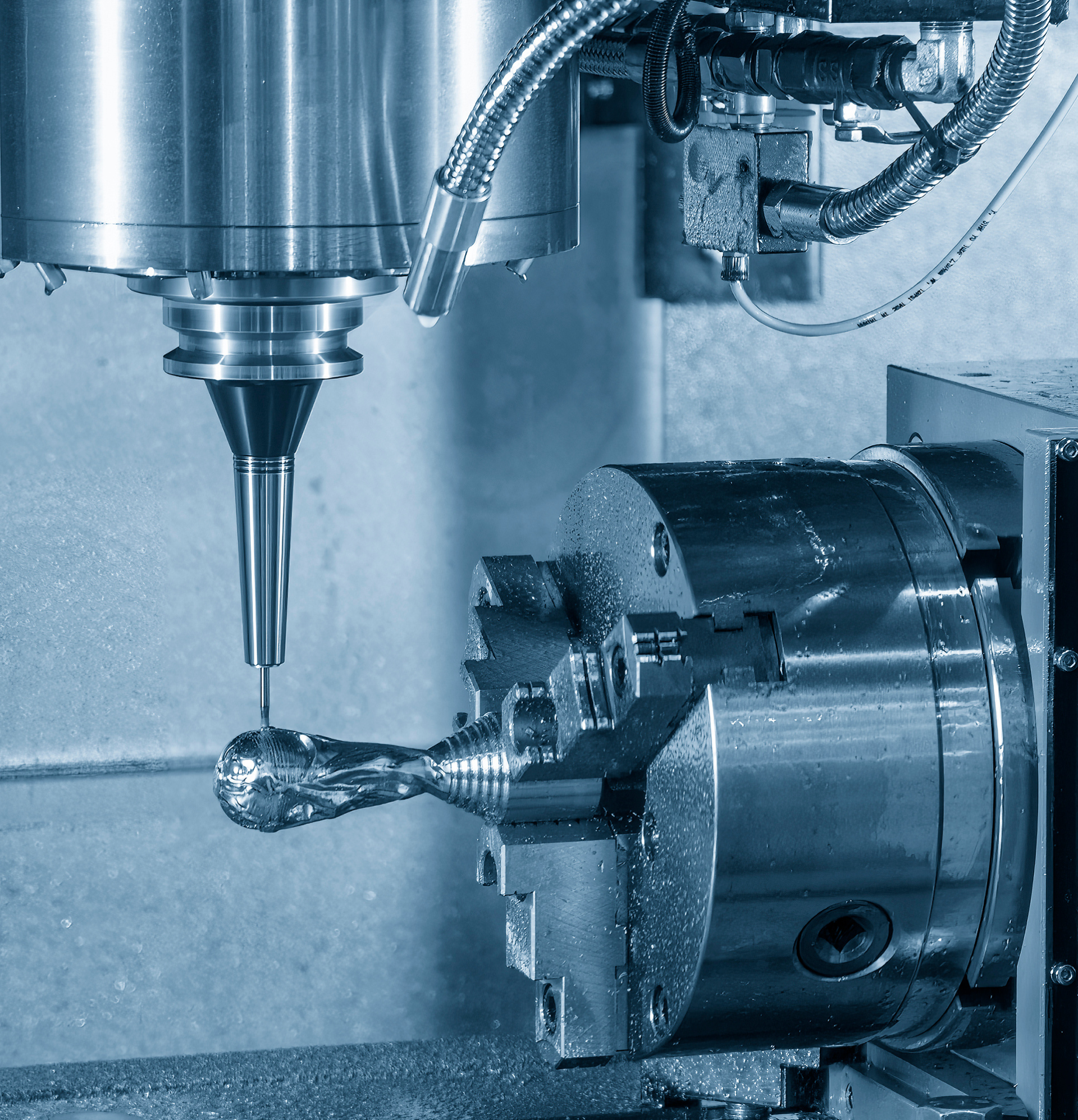

Let’s face it: productivity isn’t about working harder; it’s about working smarter. MEI gets this better than anyone. By leveraging cutting-edge tools like cryogenic and ambient grinding, MEI streamlines operations to save time, cut costs, and boost output—all without burning through resources. Their website details how they process post-industrial rubber scrap—materials like Butyl, Natural, Fluoroelastomer (FKM), SBR, Nitrile, Neoprene, and EPDM—into granules and powders from 0.375 inches to 120 mesh. This precision optimizes factory floors and workflows, delivering results that hit the bottom line.

Take their cryogenic grinding process: using liquid nitrogen to freeze rubber, MEI achieves finer particle sizes with less energy than traditional methods, producing ISO 9001:2015-certified products. Businesses report up to 30% productivity gains with MEI’s solutions—proof that doing more doesn’t mean taking more. It’s efficiency reimagined, from automotive tire treads to sports surfacing, all centralized in Ohio to cut shipping emissions.

Sustainability Isn’t a Sacrifice—It’s a Strength

Too often, “going green” feels like a compromise: slower production or higher costs. MEI flips that on its head—sustainability is the engine driving their success. At their core is a commitment to turning scrap into solutions. Their tolling service lets customers send rubber waste for grinding, while MEI’s own stock of recycled materials reduces landfill burden and virgin resource demand. This circular economy approach transforms waste into high-performing assets like playground tiles and industrial blends.

Consider their Sports Surfacing Division: colored EPDM granules, rubberized mulch, and durable tiles made from recycled rubber provide safe, long-lasting surfaces. Paired with polyurethane binders, these products cut replacement needs and waste. It’s not just feel-good recycling—it lowers energy use and carbon footprints, making sustainability a competitive edge, not a checkbox.

Evidence of MEI’s Green Edge

MEI’s practices are grounded in proven processes. Our website showcases the efficiency of cryogenic grinding—freezing rubber to achieve finer, more consistent results while using less energy than heat-based ambient grinding. Rigorous material inspection and testing throughout manufacturing ensure zero waste from defects, benefiting industries such as construction (roofing) and automotive (motor mounts). Guided by the “Quality is the Cornerstone of MEI” policy, employees are trained to prioritize precision and effectiveness, embedding sustainability into every step. With over 42 years of experience, MEI has perfected this science to deliver exceptional results.

Saving the Planet from Rubber and Plastic Chaos

Unsustainable rubber and plastic practices are wreaking havoc on the planet. Each year, over 300 million tons of plastic are produced globally, with 8 million tons ending up in oceans, killing marine life and leaching toxic chemicals into ecosystems. Rubber waste fares no better—discarded tires and industrial scraps contribute to 1.5 billion tons of landfill waste annually, releasing methane and polluting soil as they degrade over centuries. These escalating crises have fueled a soaring demand for sustainable solutions. Consumers now reject brands that ignore this toll, while businesses scramble for partners who can deliver efficiency without ecological disaster.

MEI rises to the challenge, countering these devastating effects with smarter practices. By grinding post-industrial rubber scrap into reusable granules, MEI diverts waste from landfills and oceans, resonating with trending search terms like “eco-friendly productivity” and “sustainable manufacturing.” Companies adopting MEI’s methods see reduced overhead, happier teams, and standout reputations—benefits that ripple outward to cleaner air, purer water, and a future worth building.

Showcasing Rubber Granules: Playground Perfection

Imagine a playground that’s safe, vibrant, and built to last—that’s the power of recycled rubber granules from Midwest Elastomers. Our expertly sized granules transform into colorful, cushioned surfaces that protect kids while standing up to years of play. Whether coarse for durability or fine for a smooth finish, these granules deliver a uniform look and feel, with hues ranging from earthy browns to bright reds and greens.

Beyond aesthetics, our rubber granules offer practical benefits:

- Safety First: Soft, shock-absorbing layers reduce injury risks.

- Eco-Friendly Design: Made from recycled rubber, they keep waste out of landfills.

- Low Maintenance: Weather-resistant and long-lasting, they save time and costs.

We tailor every granule to ensure your playground not only looks great but performs even better—so its ideal for the kiddos.

"The greatest threat to our planet is the belief that someone else will save it."

- Robert Swan

The MEI Mindset: A Blueprint for All

What makes MEI special isn’t just its tech—it’s the mindset. This is more than a company; it’s a philosophy anyone can adopt. Start small: optimize a process, rethink a resource, measure an outcome. MEI’s example—turning scrap into playgrounds or cutting energy with cryogenic tech—shows productivity and planet-saving can thrive together. Whether you’re a startup founder, a corporate leader, or just someone who cares, every choice for efficiency over excess channels the MEI advantage.

Ready to Tap Into the MEI Advantage?

The world’s moving fast, but MEI keeps pace without losing sight of what matters. It’s not about sacrificing tomorrow for today—it’s about a future where both flourish. From boosting productivity with smarter grinding to protecting the planet with recycled rubber, MEI proves the best way forward is the sustainable way. Ready to see what the MEI advantage can do for you? It’s more than a solution—it’s a movement. Join it, and let’s make productivity green, one brilliant step at a time.

Interested In Engaging In Eco-Friendly Production Practices?

Contact us today!

Ready to explore how to benefits your business and the environment?

Fill out the form below, and our team will connect with you to unlock innovative, sustainable rubber solutions that boost performance and safeguard the planet.